Description

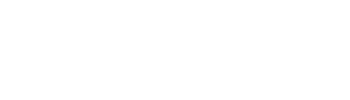

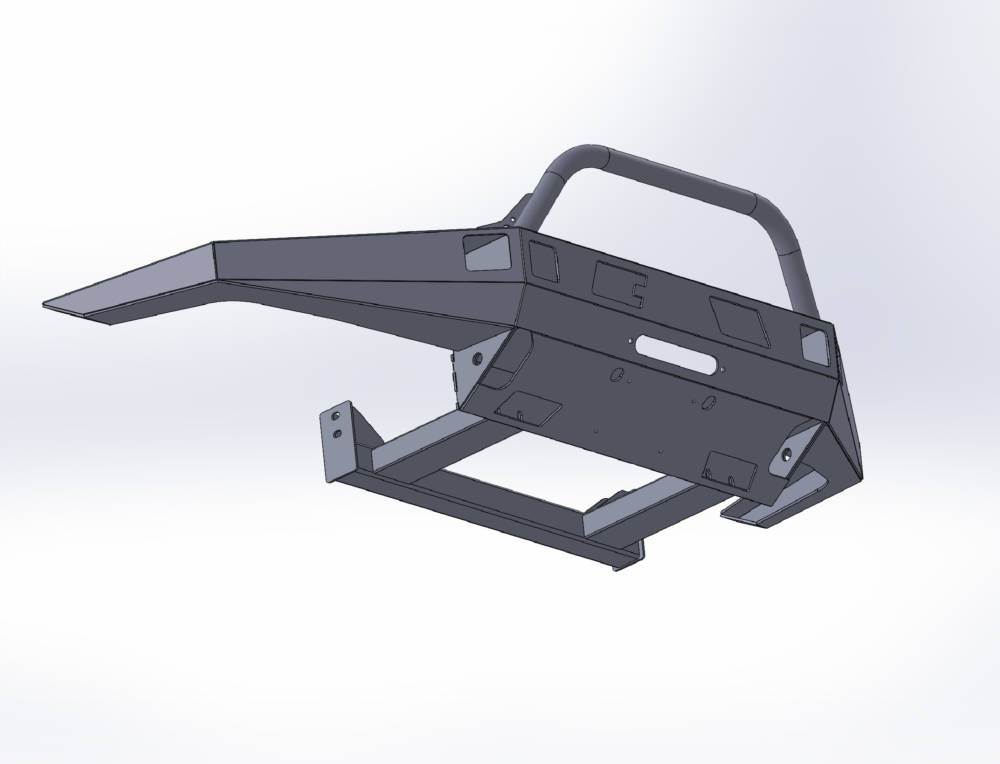

Due to the unibody construction of the T1N Dodge Sprinter van (1995-2006), there is not a lot to mount a winch bumper capable of pulling the entire weight of the van. This makes the mounting system of the bumper especially critical. If a thick steel bumper is poorly mounted to the vehicle unibody, no matter how strong the bumper is, it will simply punch through the unibody mounting points should an impact occur. So, our engineers came up with an intermediate crossmember that bolts to your Dodge Sprinter’s main structural rails approximately 18″ back from the nose of the vehicle. This bumper then mounts to this crossmember plus the front of the Dodge Sprinter’s unibody frame using a total of six 1/2″ bolts. This distributes impact and winching forces evenly across your unibody frame. As far as we know, this is by far the most serious winch bumper mounting system available for the first generation Mercedes Sprinter van and will ensure that you can rely on this bumper when you need it most.

Despite the extra mounting points, this bumper still uses two factory frame mounting points to attach it to the vehicle, meaning that there is absolutely no guess-work required when fitting the bumper to the vehicle. The factory mounting points will locate the bumper perfectly on the vehicle, and then the supplied bumper plates comes pre-cut with the holes to locate the rest of the mounting holes needed. The six 1/2″ bolts tie the winch plate of the bumper directly into the van and our suppled heavy duty crossmember, making for an extremely strong and stiff bumper that will not flex or shift under hard winching and recovery point pulls

We finished this bumper off with four integrated light buckets for surface mount LED pod lights (custom light cut outs available by request, such as a 20″ light bar version), an integrated winch mount to accept all standard 8-12k lb winches with removable solenoids, optional grill and headlight protection hoops for increased wildlife protection, and optional front hitch receiver to allow a variety of recovery and gear carrying options (available by custom request – please send us an email and we’d be happy to discuss further). The heavy duty 9/16″ thick recovery points are placed directly in line with the T1N Sprinter frame to eliminate any leveraging effects. These recovery points are formed by laser cut steel plates that pass through the bumper shell and tie directly into the T1N Sprinter frame as part of the bumper’s main mounting brackets. The recovery points then get welded to the in and outside of the bumper shell. These factors all combine to form recovery points that minimize stress on your T1N Sprinter frame and provide reliable recoveries of heavily loaded vehicles in the worst of offroad situations. What could make this bumper even better? The low profile design has resulted in very reasonable weights of 88lbs for the steel bumper and 43lbs for the aluminum version. Considering that this bumper replaces your factory bumper and associated components, the resulting weight increase to your T1N Sprinter is surprisingly minimal. This reduces added stress on your vehicle, maintains precious payload capacity, and allows you to keep your factory suspension if desired.

•DIY Weld-together kit – This bumper arrives as precision CNC-laser cut and bent pieces that you then weld together (detailed assembly instructions included)

•CNC-bent plates greatly reduces amount of welding and grinding required by you and makes for a cleaner finished product

•Low profile design is engineered to provide maximum ground clearance and complement the factory body lines

•Includes intermediate mounting crossmember which provides maximum strength for the most demanding offroad conditions

•Heavy duty 3/16″ plate steel construction for maximum offroad strength and durability

•Optional 1/4″ 5052 aluminum for a lightweight yet very durable overlanding setup (45lb weight savings)

•Protected winch mount fits all standard 8000-12,000lb winches with removable solenoids

•Reinforced 9/16″ thick clevis mounts allow the use of 3/4″ D-Rings and pull directly off of the frame for confident recoveries of heavily loaded vehicles

•Four integrated LED pod mounts – slotted mounting tabs give adjustment to fit a variety of lights

•Integrated license plate mount

•Optional heavy duty grill and headlight tubing for added protection

•Optional “Lower Cover Plates” are shown on the white sprinter van. These plates are made from heavy duty 3/16″ thick steel plate (Or 1/4″ aluminum if option selected) and provide some extra body coverage underneath the bumper side wings for those looking for a less extreme “High clearance” look to their front bumper

Reviews

There are no reviews yet.