Several years back, I wrote an article on clearing 35” tires on a 3rd generation (1998) Toyota 4Runner. At that time, Toyotas running 35” tires without the use of a huge lift were relatively uncommon. However fast forward to today and the scene has progressed hugely, both in terms of the range of aftermarket parts available and how much cutting and permanent modifications the average enthusiast is willing to do. It’s now pretty common for 35” tires and a 2-3” lift to be the go-to build on 4Runners, Tacomas and GX’s. The next logical step is 37” tires. While I will be doing an article on clearing 37” tires on a GX470 (which will also apply to the 4Runner and Tacoma) later this year, today’s article is about how to clear 37” tires on the 2007-2021 Toyota Tundra.

The Tundra has never been quite as popular as the Tacoma and 4Runner when it comes to offroad builds. It makes sense, as the Tundra is a much bigger vehicle and its increased width in particular can become a hinderance on the trail. On the flipside, Tundra’s have much more storage space and payload weight capacity and as a result, they are becoming a more and more popular choice for overland builds that are more geared towards exploration and camping. And lets be real, its also sort of just the natural progression of the life of a Toyota truck owner: you own a Tacoma and then you sell it to buy a 4-door Tundra once the babies start arriving. So instead of talking about the usual Tacoma and 4Runner firewall and body mount mods (of which there are a million articles/videos out there), today we’ll be going through the details on clearing 37” tires on a Tundra at ANY ride height.

Let me start out by saying the 2007-2021 Tundra has far more space in the wheel wells to begin with when compared to a Tacoma or 4Runner. From my experience, I would go as far as to say that clearing 37” tires on a Tundra is actually easier than clearing 35” tires on a Tacoma/4Runner. However, there are some key details to keep in mind that make this possible. This how-to article will allow you to clear 37” tires at any ride height. This includes a bone stock Tundra with no lift at all! Now this may sound very counter-intuitive to you and I don’t blame you one bit for thinking that way. It’s commonly taught that lifts are how you fit larger tires on any vehicle. While that is true in some ways, lifts do not provide true tire clearance throughout the suspension travel range. For an in-depth explanation on this, please see our previously mentioned article where I dive into the mechanics of the suspension and show why a suspension lift will not actually help you clear those big tires.

There are two huge added bonuses that make is easier to clear 37” tires on the Tundra. First off, no cutting of the actual outer fenders is required to fit 37” tires. All of the clearancing work will be hidden inside the wheel wheels and out of sight. This takes a lot of the anxiety out of this job for those who are a little hesitant about cutting into their Tundra. Even if your work isn’t the prettiest, you can at least rest assured it will be out of sight! Unless someone sticks their head inside the wheel well, the truck will appear completely stock and unmodified. Secondly, a true firewall tub is NOT required. A firewall tub is where you cut a big hole into the interior of your vehicle and start trading leg room for tire room. On the Tundra, you only need to deal with the pinch weld seam and body mount. Your interior remains fully intact and this also makes this whole clearancing process much less intimidating.

Disclaimer: This article is simply an informational resource to give you an idea of what is required to tub a vehicle for oversized tires before deciding to attempt it yourself. Coastal Offroad nor myself are responsible for any problems you encounter while performing these modifications on your own vehicle.

WHAT YOU’LL NEED:

1. Floor Jack

2. Jack Stands

3. Wrench and socket set

4. Pipe wrench or adjustable wrench capable of expanding to 2.25” in size

5. Welder – MIG, TIG or Stick will work

6. Basic Welding Items – Welding mask, Heat resistant gloves, welding pliers

7. 4-5” angle grinder

8. Smaller die grinder (optional, though can provide easier access in tight areas)

9. Metal cutting disks (makes sure you don’t buy masonry disks by accident lol)

10. Flap disks

11. Masking tape

12. Sharpie marker

13. Polyurethane sealant

14. Primer

15. Rubberized undercoating or bedliner

16. Cab Mount Chop Plate Kit

17. Bumpstop Spacer Kit (Optional but recommended)

18. Front Bumper Shim Kit (Optional – see details for when this is required)

As a side note, If you want to take the easiest possible route into the 37’s club, go with a BFG KO2 All terrain tire. They are known to be the most undersized tire on the market and will be the easiest to fit.

Front bumper and sway bar

The truck pictured in this article is running a Coastal Offroad front bumper. This bumper is specifically designed to clear 37” tires at full compression and lock to lock steering so no clearancing work is required here. However, if you have the factory front bumper or an aftermarket bumper from a different manufacturer, you may need to trim it or add spacers to push it forwards. The first option is to trim about 1” off of the bumper and fender liner in the area closest to the wheel well to gain enough clearance for the tires. The second option is to simply install shim plates onto the frame end plates (as shown below) to push the bumper forwards. This is the easiest solution and again avoids the need to make visible cuts on the exterior of your vehicle. Those shim plates can be found here.

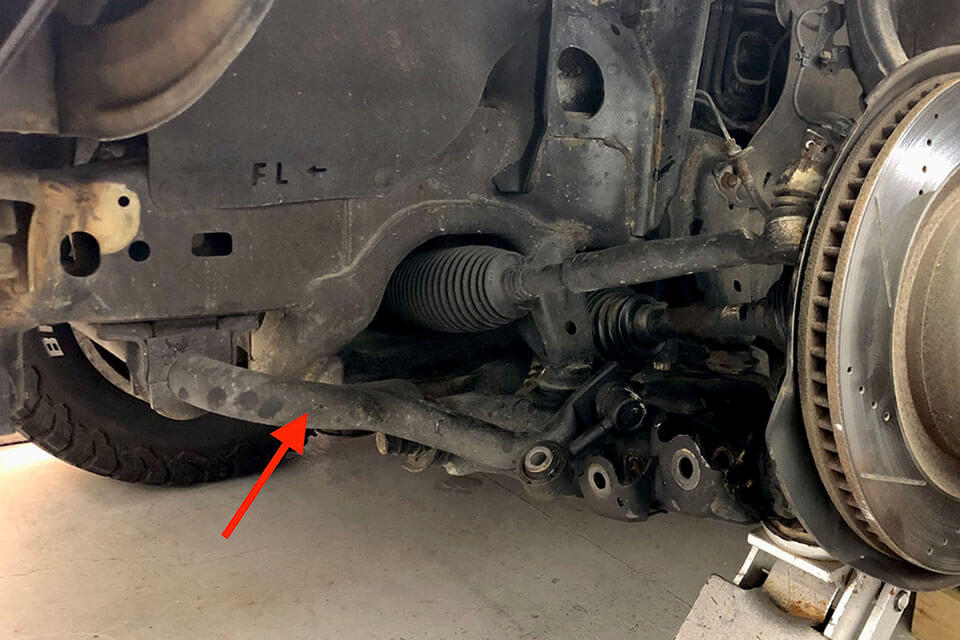

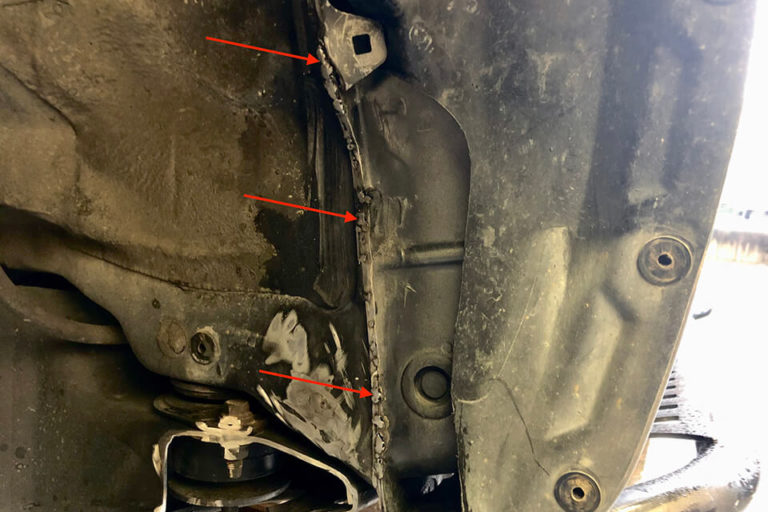

Now for the front sway bar. It seems to be the norm for Tundra owners to ditch their front sway bar whenever making the jump to 37” tires. Yes, 37’s will rub on the sway bar at full lock steering in the location indicated by the red arrow (pictured below). However, I found that this occurs so close to max lock steering that you really aren’t losing much turning radius at all by keeping the sway bar on. Yes, your tire will rub the paint off your sway bar but this is honestly the worst thing that will happen. The tire will touch the sway bar in a location where it’s a smooth, rounded bar so its not going to cut into your nice new 37’s or cause any other damage. So depending on your intended uses for your Tundra, keep the sway bar on or remove it. Either way will be just fine.

Great stories are for everyone even when only written for just one person. If you try to write with a wide, general audience in mind, your story will sound fake and lack emotion. No one will be interested. Write for one person. If it’s genuine for the one, it’s genuine for the rest.

What about using my wheel alignment specs to gain extra tire clearance ?

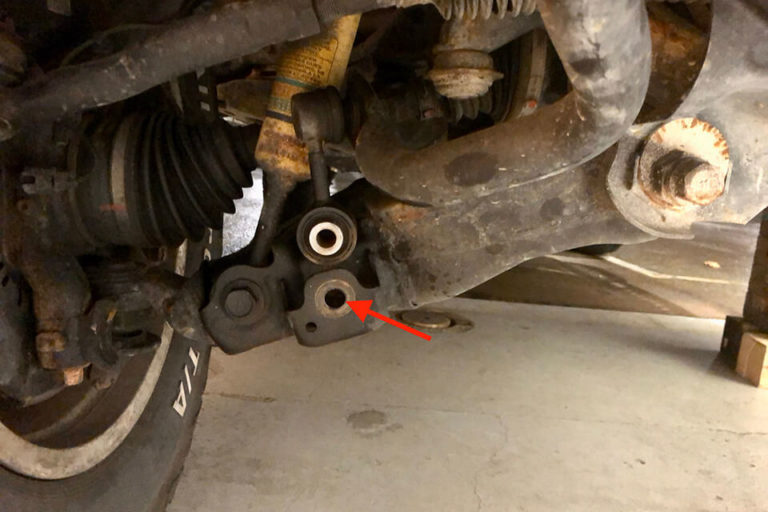

A commonly talked about method of gaining a little extra tire clearance around the body mount and firewall is to push the tires forwards using the factory alignment cams. This is done by maxing out the front alignment cams inwards and the rear alignment cams outwards. This tilts the lower control arms forwards and maximizes your caster angle. While this may buy you a little bit of extra tire clearance, there is debate on whether this causes excessive bushing wear and component damage over time. Since you are maxing out the front alignment cam in one direction and maxing out the rear cam in the opposite direction, your lower control arm will end up at a slight angle within its mounts which is never ideal. This method also requires the use of aftermarket adjustable upper control arms to get your camber angle back into spec. And depending on your area, it may be tough to find an alignment shop who is even willing to do this type of alignment for you. So in short, yes this method can give you a little bit of extra tire clearance around your body mount and firewall pinch weld, but it is not mandatory and I personally would avoid it.

Starting the clearance process

So you’ve chosen your wheels and tires, collected the required tools and supplies you’ll need, and read up on our previous article to better understand our goal of achieving no tire rub at full compression and lock to lock steering. It’s now time to start the process of clearancing your Tundra’s wheel wells.1. Jack up the front end of your vehicle and support it on jack stands. Ensure that your jack stands are positioned so that your 37” tires have space to turn lock to lock without hitting the jack stands. Remove your front wheels.

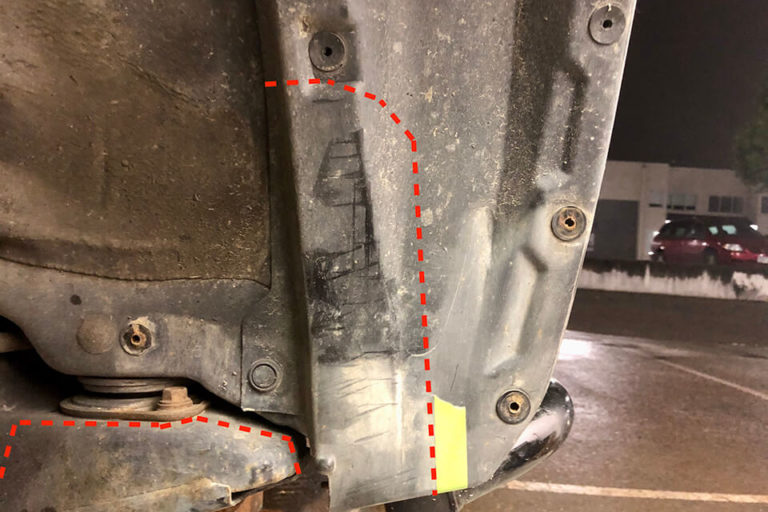

7. Upon doing this, you will quickly realize that the worst area for rubbing is at the back of the wheel well where the firewall and body mount are located. From here, the clearancing will become an iterative process of removing the wheel and tire, doing a little trimming, re-installing the tire, rechecking the clearance and repeating.

14. First, spray a bit of primer on the pinch weld seam area that you previously cut, tacked and sanded down. This will protect any small exposed pin holes or tight areas where the sealant may not flow fully. Next, apply the polyurethane sealant to the pinch weld seam cut. Apply this sealant liberally to the area all around the pinch weld seam cut.

Bumpstop spacers ( optional but recommanded )

Now I know what you’re thinking, but first let me explain! Bumpstop spacers are spacers that you add between your suspension bumpstops and the vehicle frame. These spacers lower your bumpstops so that your suspension will bottom out sooner. Yes, this means reduced overall suspension travel and this is why some people will laugh at me for even suggesting them. Normally, I am also against limiting suspension travel for the sake of reduced tire rub and this whole article is based around clearing big tires throughout the suspension’s entire travel range. HOWEVER, in the case of running 37” tires on the tundra, I am making an exception by adding some tiny bump stop spacers and here is why:

With a 37” tire jacked up to full compression using the method given in this article, the tire will not hit the top of the fender but it will be within a couple millimeters of it. Remember that ‘small caveat’ I mentioned earlier on? When you are out in the wilderness and encounter a hard suspension bottom-out situation, such as bumping a ledge obstacle to get up it or hitting an unexpectedly big dip on an FSR a little too fast, the suspension will compress (just as we simulated in the shop). Plus, there will also be flex in the vehicle chassis, body mounts, suspension bushings, etc that will result in the tires compressing a little bit further than what we can replicate in the shop. For this reason, its important to ensure that we give the tires at least an extra ½” of space to account for the additional flex and movement that will occur within the vehicle during a hard bottom out. My solution is to add a 3/16” thick front bumpstop spacer and a ¼” thick rear bumpstop spacer. Due to the relationships between the suspension pivot points, bumpstop locations, and tire location, this will result in a wheel travel reduction of just about ½” which is perfect.

So yes, you will theoretically lose ½” of wheel travel, but this is wheel travel at the very end of the travel range that will only be reached during hard bottom-out situations. If you’d prefer to avoid the bumpstop spacers, the alternative is to cut and re-seal the vehicle’s outer fenders and remove the inner fender liners altogether. This adds a lot of work to the overall procedure, as well as visible cutting and modifications to the vehicle’s outer fenders that risks premature rusting if not sealed properly. If I was running an expensive long travel setup, I absolutely would do this. However, if you are running stock lower control arms with a typical lift or “mid travel” kit, you’re not losing any real suspension performance by limiting that last ½” of fender-crunching wheel travel.

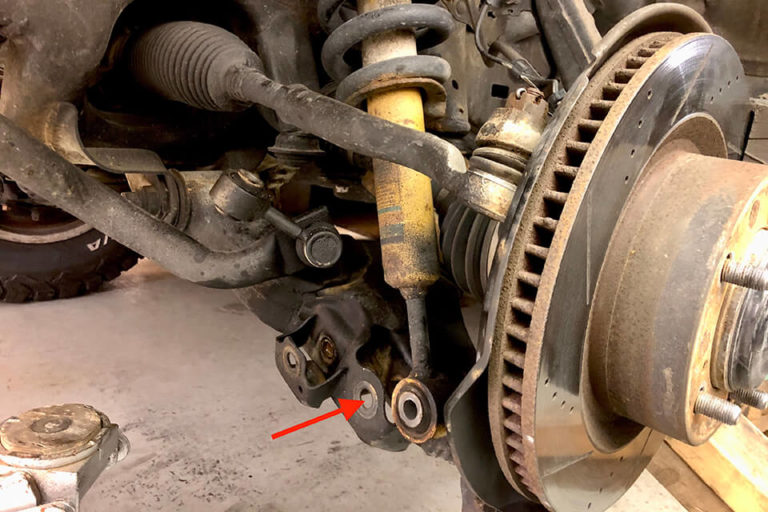

19. To install the bumpstop spacers, first remove the 2 bumpstop spacers using your pipe wrench opened up to 2.25” wide. Be sure to keep track of which bumpstop is the front and which one is the rear.

21. Reinstall the bumpstops back onto the vehicle. You can see in the picture below that the bumpstop spacers are now sitting between the bottom of the frame and the top of the bumpstop spacers.

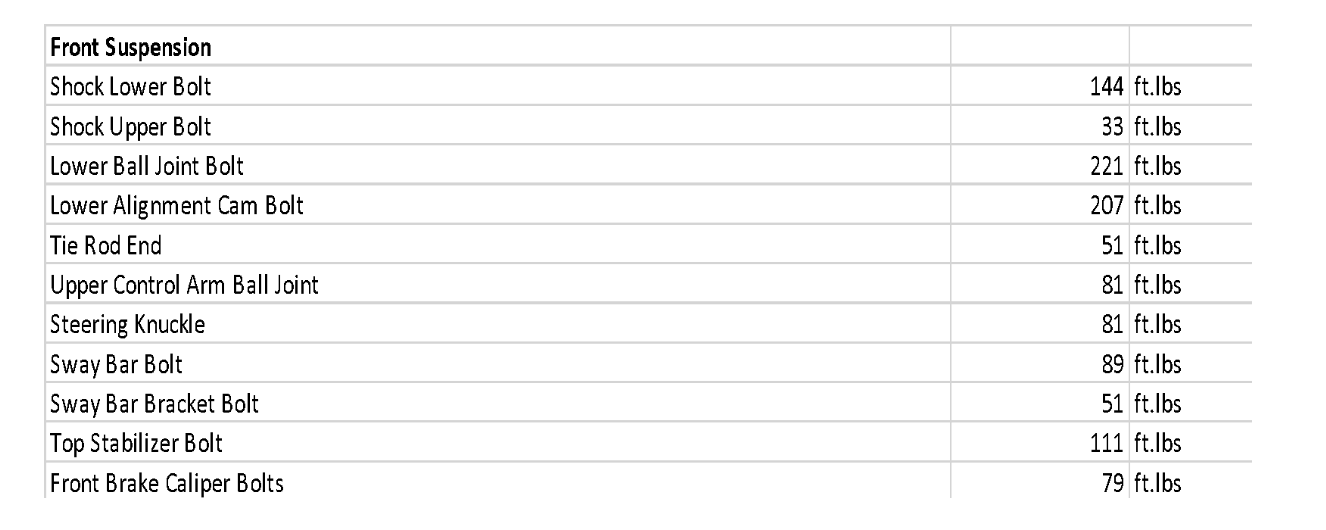

22. You may now reinstall all of the front suspension components that you removed at the start of this procedure. I have included a table with all of the common front suspension torque specs for the Tundra. These are the torque specs that I use, but always refer to Toyota’s official service manuals to verify. Be sure to re-check all bolt torques periodically.

Clearancing for the rear tires

Unlike the front, fitment of 37” tires in the rear of the vehicle requires little to no work. A critical part in achieving this is again the wheel offset. With my +15 offset on these wheels, the tires will tuck under the outer fender during suspension articulation. With a 0 offset wheel, this will not be the case and you will need to trim the outer fender to eliminate that rubbing. The truck pictured in this article still has stock leaf springs and shocks with airbags added for carrying additional weight in the bed. If you are running aftermarket leaf springs and shocks that give you more articulation, the more extreme axle angles will cause your 37” tires to rub on the inner fender liners. To eliminate this rubbing, you can push the fender liners back as needed or remove them altogether.